Production Equipment

Our facility is equipped to support composite manufacturing programs from material preparation through cure, machining, and final finish — all performed internally.

Autoclaves & Thermal Processing

Multiple Autoclaves (up to 8 ft dia × 50 ft long)

Thermal Processing Capability (up to 350°F, 100 psi)

Multiple autoclaves for consistent, aerospace-grade composite curing across a wide range of part sizes.

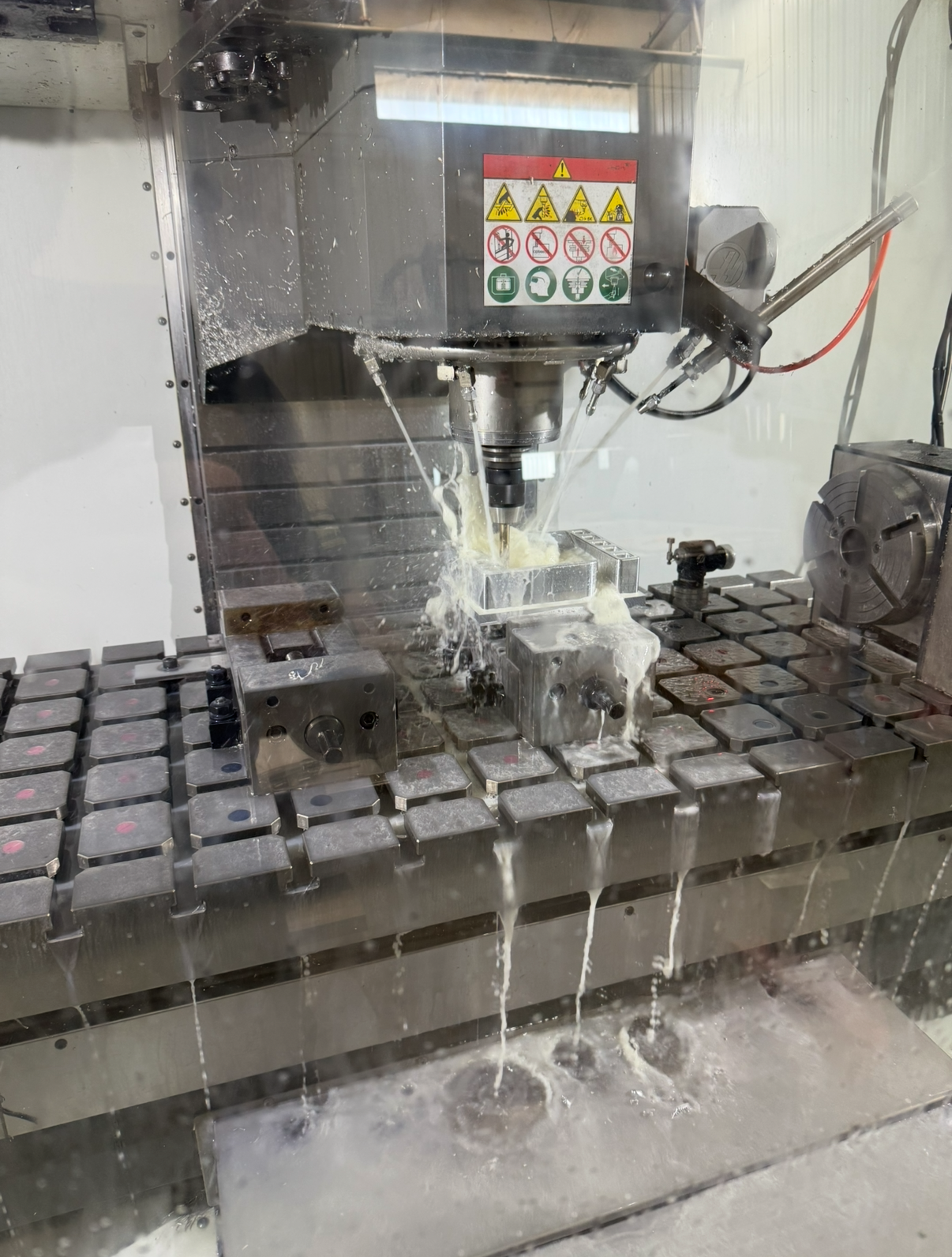

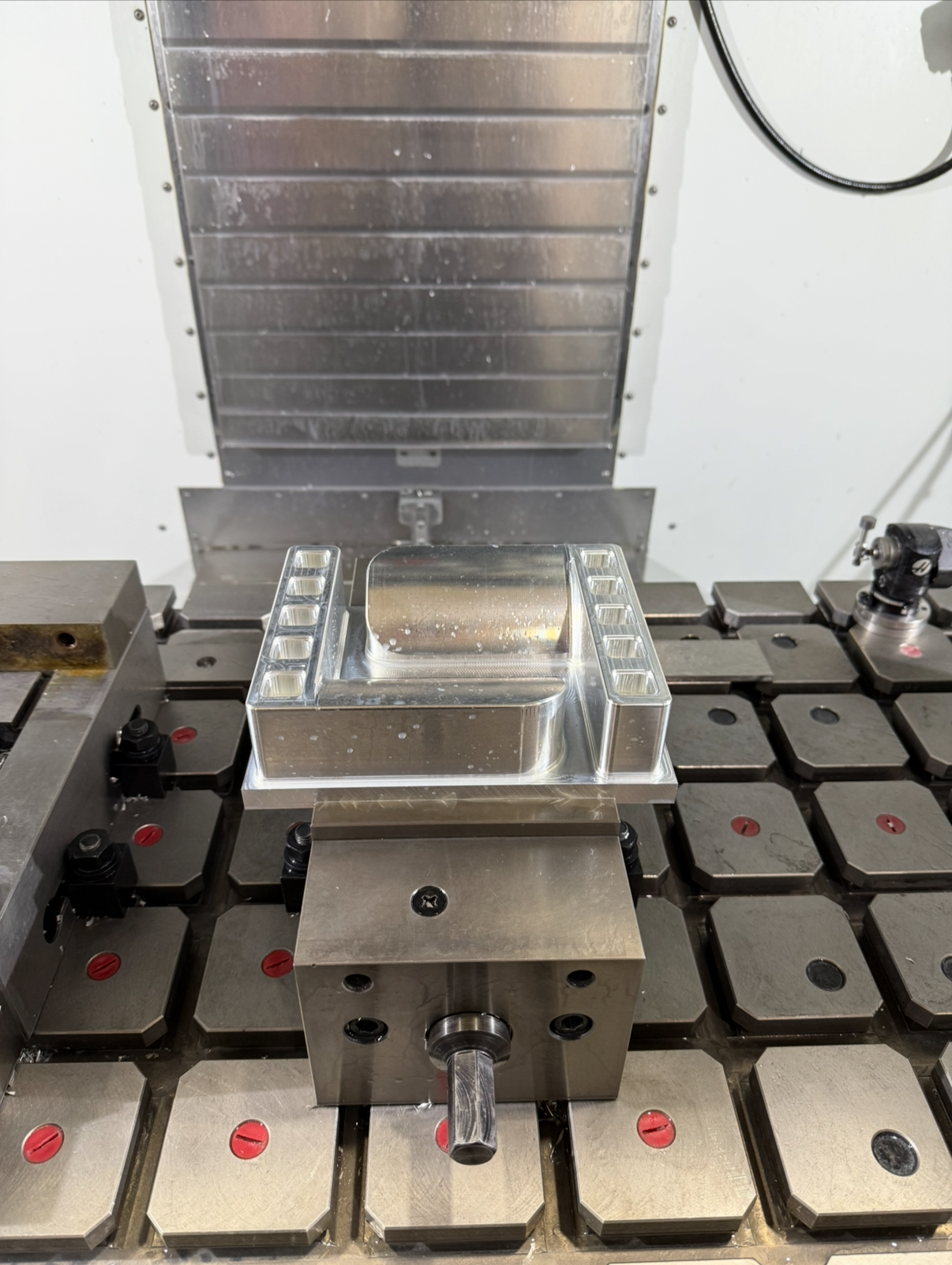

CNC Machining & Routing

Zimmerman 5-Axis CNC Mill

Haas GR-712 3-Axis Gantry Router

Haas VM-3 Vertical Mold Machine

Rigid, large-format 5-axis milling for complex surfaces, molds, and tight-tolerance features—capable across aluminum, steel, plastics, and composite-related materials where stability and finish quality matter.

High-precision gantry machining for aerospace parts, tools, and molds, built for clean edges, stable geometry, and repeatable results—from large-format panels to high-volume detail parts.

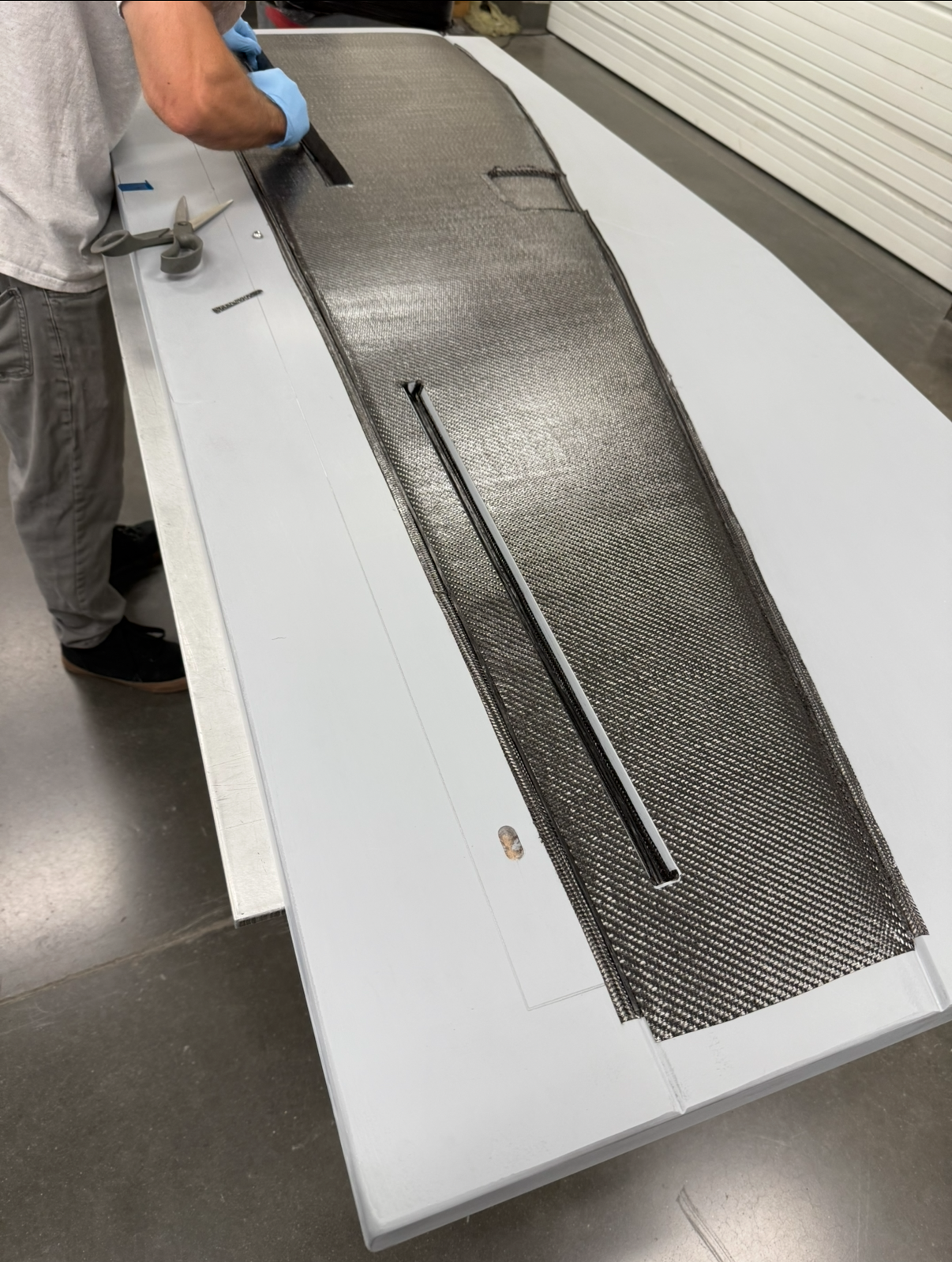

Cutting, Trimming & Inspection

Lectra CNC Cutting Table

Multiple Trimming Routers

Keyence CMM

Fabrication and measurement capabilities that support consistent output from prototype through production. Traceable ply cutting with efficient nesting to reduce scrap, repeatable trimming and edge finishing, and dimensional inspection to verify critical features and conformity.